SCADA project for the control of a line of 4 heat treatment furnaces, dedicated to treating railway brake discs.

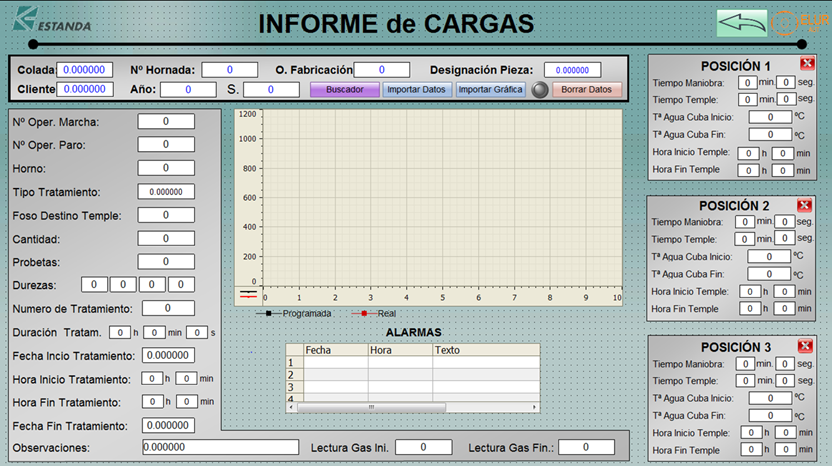

The objective is to carry out the traceability of the pieces based on a record in a database of the treatment curve and various parameters of the oven control.

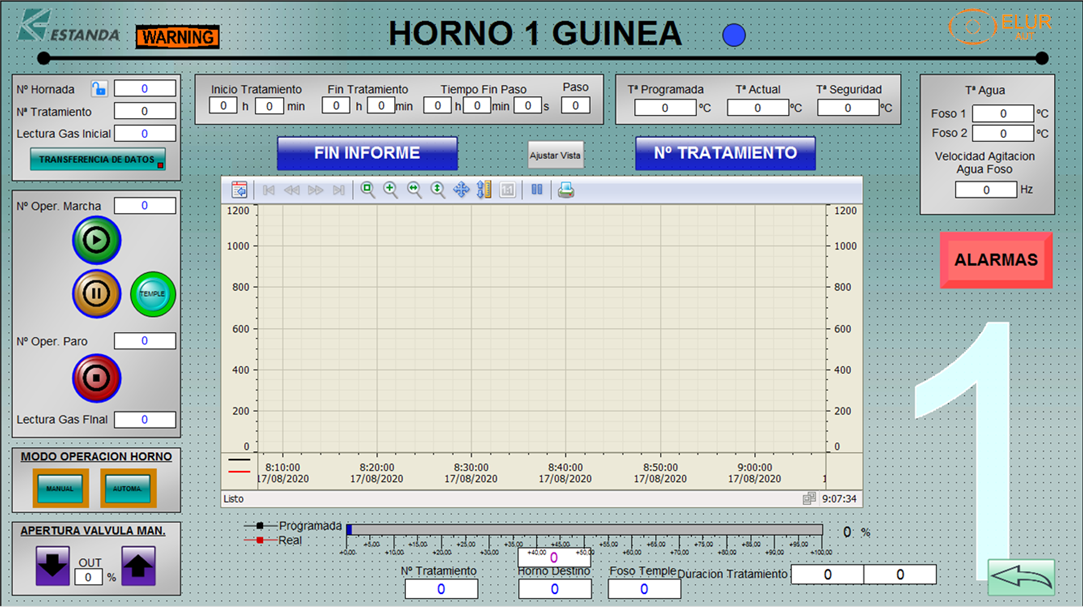

In SCADA, the different heating curves are edited and stored in a database.

The operator generates the batch with customer data and selects the heating curve and then the SCADA controls the oven until the end of the cycle.

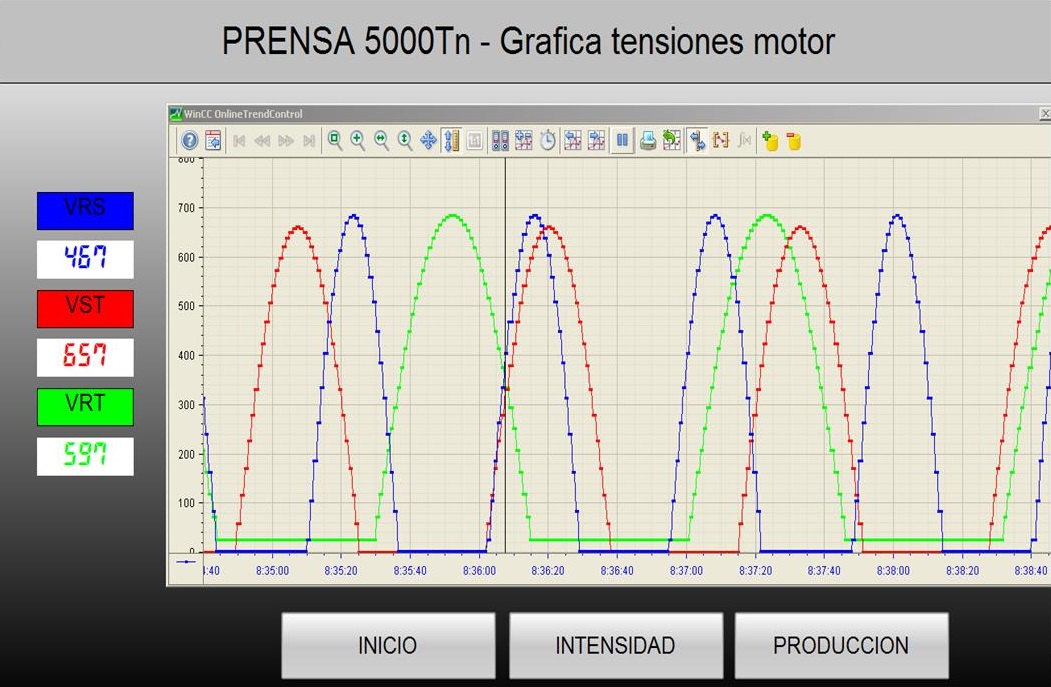

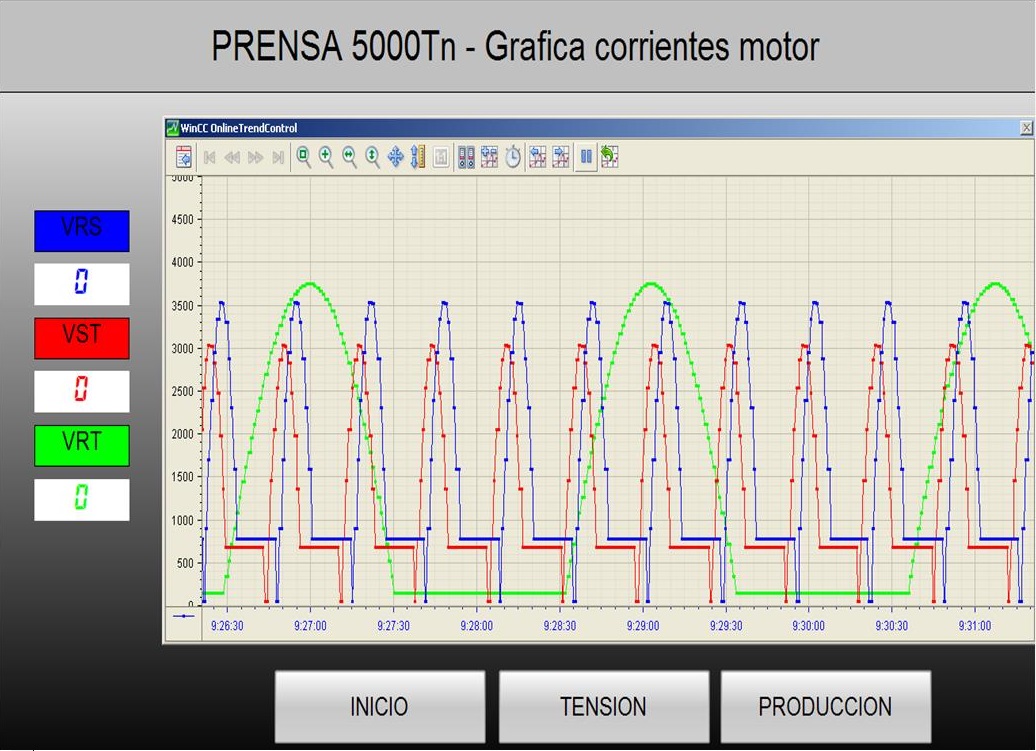

To carry out this project, PLC and SIEMENS software have been used, the SCADA has been carried out with the WINCC software and the communication used has been PROFINET, since temperature records of each oven are made every 5 seconds for the generation of graphics .

Related Posts

-

SCADA FORGE LINES

SCADA for the visualization, control and parameterization of a forging cell with robots, which has been... -

Scada Control Robot

This SCADA, based on the geometry of the selected box and previous programming of variables by the operator,... -

Arm Paint

Design and manufacture of equipment to control a painting arm with vertical movement. The arm, originally,... -

Deep Cardboard Packaging Line

This line transforms corrugated cardboard sheets into perfectly shaped and printed packaging boxes, with... -

Continuous heat treatment furnace

Automation project of an automatic continuous line with 2 chambers for heat treatments. The electrical...