SCADA project to control a line of 4 heat treatment furnaces, dedicated to treating railway brake discs, carried out for STANDARD FOUNDRY.

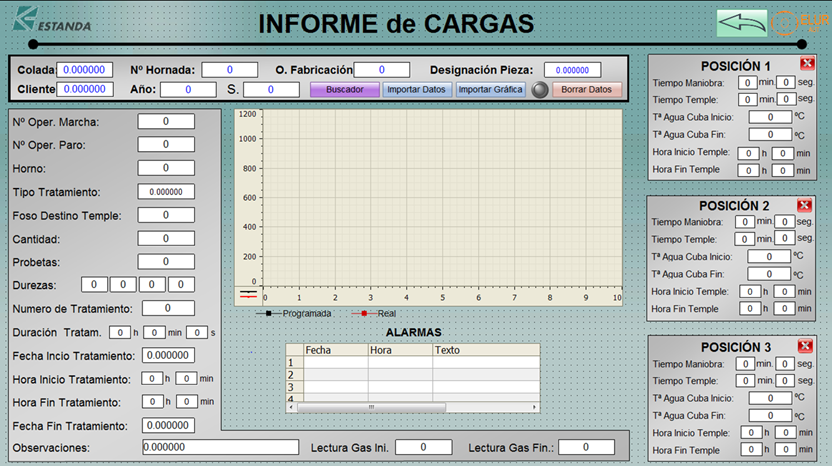

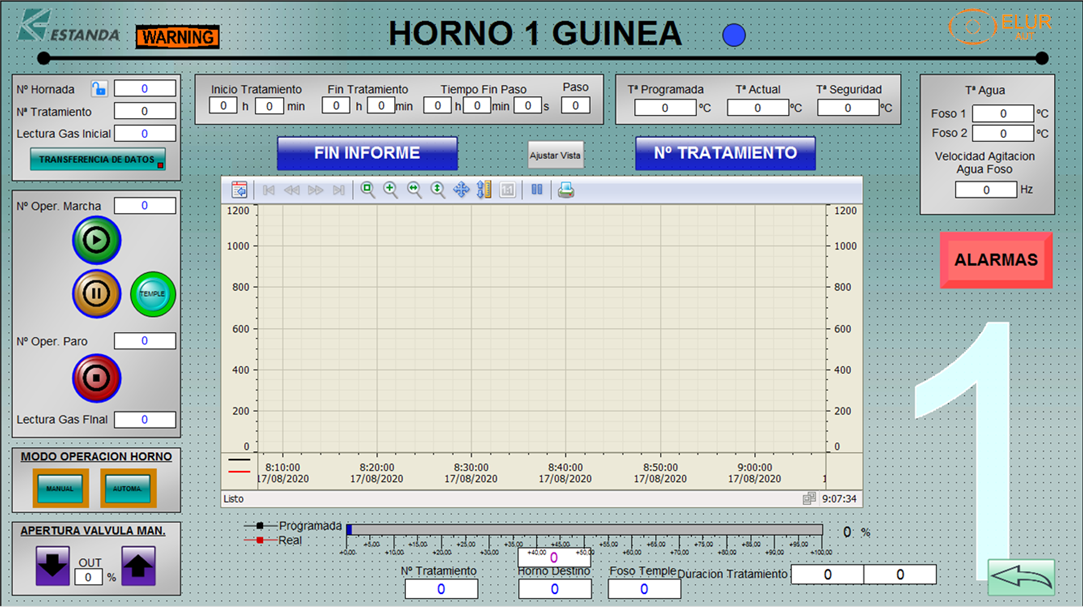

The objective is to carry out the traceability of the pieces based on a record in a database of the treatment curve and various parameters that intervene in the process.

In SCADA, the different heating curves are edited and stored in a database.

The operator generates the batch with customer data and selects the heating curve and then the SCADA controls the oven until the end of the cycle.

Related Posts

-

SCADA FORGE LINES

SCADA for the visualization, control and parameterization of a forging cell with robots, which has been... -

Scada Control Robot

This SCADA, based on the geometry of the selected box and previous programming of variables by the operator,... -

Arm Paint

Design and manufacture of equipment to control a painting arm with vertical movement. The arm, originally,... -

Scada Motor 1000KW

SCADA project for the control of a line of 4 heat treatment furnaces, dedicated to treating railway brake... -

Deep Cardboard Packaging Line

This line transforms corrugated cardboard sheets into perfectly shaped and printed packaging boxes, with...